5-Axis CNC Machining of Micro-Optic Components with Sub-Micron Tolerances

Imagine a camera lens for space missions or a laser component for medical devices. If these parts deviate by even a micron, performance fails. That’s where 5-axis CNC machining shines. Unlike conventional methods, our technology crafts micro-optic components—like aspherical lenses and freeform surfaces—with sub-micron tolerances (as tight as ±0.1 µm) . For industries demanding perfection (aerospace, medical, defense), this precision isn’t optional—it’s mission-critical.

Your Competitive Edge: Advanced Technology & Expertise

1. Cutting-Edge Equipment

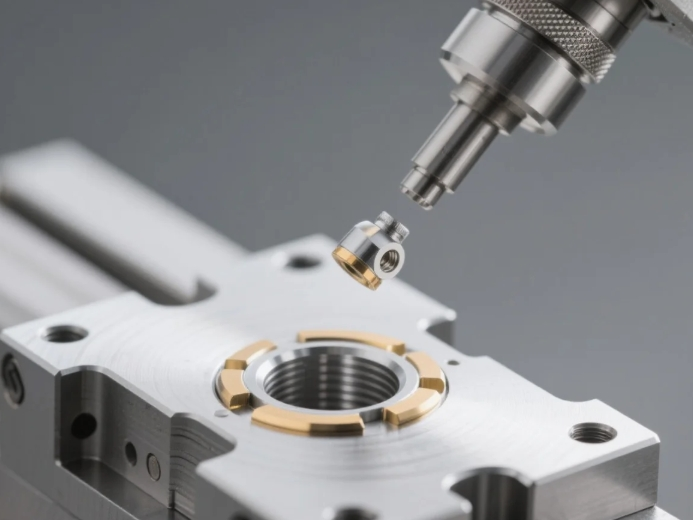

We deploy ultra-precision 5-axis CNC mills equipped with diamond-cutting tools. These machines move simultaneously across five axes, enabling complex geometries unreachable by 3-axis systems . Result? Flawless surface finishes under 0.1 µm Ra and dimensional accuracy down to sub-micron levels .

2. Masterful Craftsmanship

Precision isn’t just about machines—it’s about skill. Our team combines:

• Tool-tip radius control to minimize waviness

• Real-time tool compensation for thermal/mechanical drift

Vibration-free machining to maintain integrity during cutting

This expertise lets us handle materials from titanium to optical-grade plastics (PEEK, UHMW) without compromising precision

3. Rigorous Quality Control

Every component undergoes multi-stage validation:

• In-process metrology using sub-micron optical measurement systems

• ISO 2768 Fine Standard compliance for tolerances

• 3D CAD deviation analysis to ensure ±10% linewidth tolerance on critical features

Our goal? Zero defects, every time.

Versatility Meets Innovation: What We Manufacture

From prototypes to high-volume production, we specialize in:

• Micro-optics: Camera lenses, laser collimators, fiber-optic connectors

• Custom geometries: Freeform surfaces, microlens arrays, diffractive elements

• Industry-specific solutions: Aerospace sensors, medical imaging devices, defense optics

With 5-axis flexibility, we adapt to your design—no matter how intricate .

Beyond Delivery: Partnership-Driven Support

We don’t just ship parts; we build relationships. Our comprehensive service includes:

• Design-for-manufacturability (DFM) feedback to optimize costs/tolerances

• Expedited prototyping (as fast as 72 hours)

• Lifetime technical support for maintenance/upgrades

Your success is our benchmark.

Why Choose Us?

"With 5-axis machining, we craft all five sides of a part without re-fixturing—eliminating errors and accelerating lead times."

— Tom Ferrara, Manufacturing Expert

We merge cutting-edge technology, uncompromising quality, and customer-centric agility. Whether you need 10 units or 10,000, we deliver precision that outperforms.

Q:What’s your business scope?

A: OEM Service. Our business scope are CNC lathe processed, turning,stamping,etc.

Q.How to contact us ?

A:You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp, Skype as you like.

Q.What information should I give to you for inquiry?

A:If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect .

Q.What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment.

Q.What about the payment terms?

A: Generally EXW OR FOB Shenzhen 100% T/T in advance,and we can also consult accroding to your requirement.