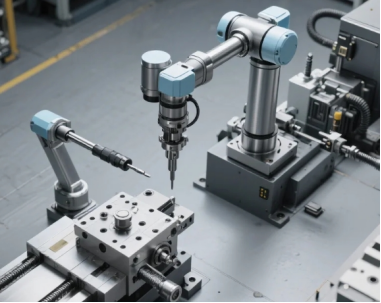

CNC Engineered Solutions for Prototyping and Mass-Production Machinery

In today’s fast-paced industrial landscape, precision and reliability are non-negotiable. At PFT, we specialize in delivering CNC-engineered solutions that bridge prototyping and mass production, ensuring seamless transitions from concept to high-volume output. With 20+ years of expertise, our factory combines cutting-edge technology, rigorous quality control, and customer-centric services to redefine manufacturing excellence.

Why Partner with Us?

1. Advanced Manufacturing Infrastructure

Our factory houses state-of-the-art CNC machinery, including 5-axis milling centers, multi-tasking lathes, and robotic automation systems from industry leaders like Haas Automation and DMG MORI. These tools enable us to achieve ±0.005 mm tolerances for complex geometries in materials ranging from aerospace-grade aluminum to hardened tool steels.

Key capabilities:

- Rapid prototyping with 48-hour turnaround times.

- High-volume production scalability (up to 50,000+ units/month).

- Customized solutions for industries like automotive, medical devices, and renewable energy.

2. Craftsmanship Meets Innovation

Our engineers leverage AI-driven CAD/CAM software to optimize toolpaths and minimize material waste, while skilled technicians apply Swiss-style machining principles for unparalleled surface finishes. Case in point: A recent project for a European automotive client reduced post-processing costs by 30% through our proprietary adaptive machining algorithms.

Quality Control: Built into Every Layer

We adhere to ISO 9001:2015 and IATF 16949 standards, ensuring compliance with global automotive quality benchmarks. Our 4-stage inspection process includes:

- Real-time CMM (Coordinate Measuring Machine) verification.

- Spectroscopic material analysis to validate alloy composition.

- Surface roughness testing using Mitutoyo Surftest SJ-410.

- Final audit by third-party labs like TÜV SÜD for critical aerospace components.

This meticulous approach has earned us a 99.7% defect-free delivery rate across 500+ projects since 2025.

Diverse Product Portfolio

Whether you need low-volume precision prototypes or high-throughput production runs, our solutions cater to:

- Custom CNC machined parts: Gears, housings, and hydraulic components.

- Turnkey assembly services: Integrated with IoT-enabled quality tracking.

- Niche applications: Biocompatible implants (ISO 13485 certified) and semiconductor tooling.

Case Study: A medical device manufacturer reduced lead times by 40% using our hybrid additive-subtractive manufacturing workflow for titanium spinal implants.

Seamless Support, From Start to Finish

We prioritize long-term partnerships through:

- 24/7 technical support via live chat and on-site engineers.

- Extended warranties covering machinery wear-and-tear for up to 5 years.

- Transparent project portals with real-time progress updates and DFM (Design for Manufacturing) feedback.

Application

FAQ

Q:What’s your business scope?

A: OEM Service. Our business scope are CNC lathe processed, turning,stamping,etc.

Q.How to contact us ?

A:You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp, Skype as you like.

Q.What information should I give to you for inquiry?

A:If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect .

Q.What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment.

Q.What about the payment terms?

A: Generally EXW OR FOB Shenzhen 100% T/T in advance,and we can also consult accroding to your requirement.